Increase Efficiency With Aftermarket Parts: an Overview for Heavy Machinery Owners

Advantages of Aftermarket Parts

Proprietors of heavy machinery can appreciate countless advantages by choosing for aftermarket parts over initial tools maker (OEM) parts. Aftermarket parts are typically extra affordable than OEM components, permitting machinery owners to reduce upkeep and repair service expenses without compromising on quality.

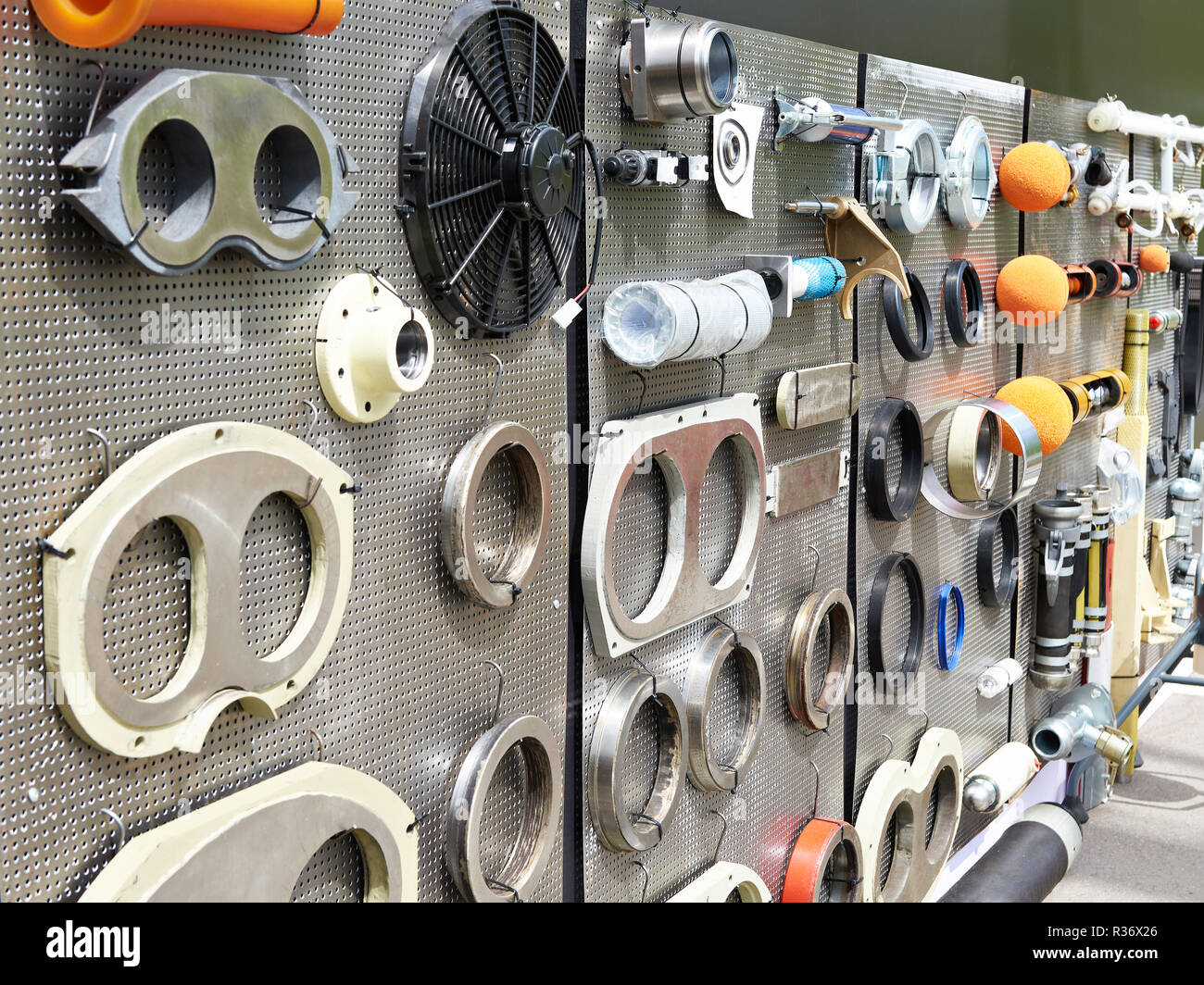

Considering that aftermarket manufacturers specialize in creating specific elements, equipment owners have accessibility to a more comprehensive variety of options to suit their demands. Aftermarket components are known for their top quality and reliability, with lots of conference or exceeding OEM requirements.

Last but not least, picking aftermarket parts can likewise lead to faster fixings and decreased downtime. With much easier schedule and quick shipping choices, equipment proprietors can obtain their equipment up and running again quickly, decreasing disruptions to their operations.

Choosing the Right Aftermarket Parts

When thinking about aftermarket components for hefty equipment, it is vital to prioritize compatibility and high quality to make sure optimum efficiency and long life of the tools. Picking the right aftermarket parts can be a vital decision for heavy machinery owners as it directly impacts the efficiency and reliability of their equipment.

Secondly, quality should never be compromised when picking aftermarket components (aftermarket construction parts). Going with high-quality parts makes certain durability, reliability, and total efficiency of the equipment. It is recommended to source aftermarket parts from reputable manufacturers or distributors recognized for their high quality requirements

Additionally, considering variables such as guarantees, client reviews, and compatibility with existing systems can better assist in making the ideal choice. By prioritizing compatibility and top quality when choosing aftermarket parts, hefty equipment owners can boost the effectiveness and longevity of their tools.

Installment and Upkeep Tips

For reliable procedure and long life of hefty equipment, appropriate setup and routine maintenance are critical. When installing aftermarket parts, ensure that you carefully follow the supplier's guidelines to assure optimum efficiency. By prioritizing installation and maintenance treatments, you can maximize the performance and life-span of your hefty machinery, ultimately conserving time and cash in the lengthy run.

Cost-Effectiveness of Aftermarket Parts

Proper installment visite site and normal maintenance are foundational facets for hefty machinery owners intending to analyze the cost-effectiveness of aftermarket parts for their equipment. While original tools maker (OEM) parts are understood for their high quality, aftermarket parts supply a more affordable solution without compromising performance. The cost-effectiveness of aftermarket parts becomes evident in numerous methods. Firstly, aftermarket visit this web-site components are normally much more budget friendly ahead of time, enabling proprietors to accomplish financial savings on preliminary purchase expenses. Additionally, these components usually supply equivalent performance to OEM parts, guaranteeing that the equipment runs efficiently without the requirement for pricey replacements. The accessibility of aftermarket components from a wide range of vendors advertises competitors, leading to affordable pricing and further cost savings for owners. By very carefully reviewing the quality and compatibility of aftermarket parts with their machinery, owners can strike a balance between cost-effectiveness and performance, eventually making the most of the effectiveness and durability of their heavy devices.

Maximizing Performance With Aftermarket Upgrades

To boost operational performance and performance, hefty machinery proprietors can properly make best use of performance with strategic application of aftermarket upgrades. Aftermarket upgrades use the chance to customize heavy machinery to certain operational demands, leading to improved capability and outcome. Updating elements such as engines, transmissions, hydraulic systems, and tracks can considerably enhance the total effectiveness of the machinery.

Routinely analyzing the performance of heavy equipment and recognizing areas where aftermarket upgrades can be useful is essential for optimizing performance. By buying high quality aftermarket components and upgrades, equipment proprietors can achieve higher levels of effectiveness, eventually a fantastic read bring about cost savings and improved operational results.

Final Thought

Finally, aftermarket components offer various benefits for heavy machinery owners, consisting of cost-effectiveness, boosted performance, and modification alternatives. By choosing the right aftermarket parts, following proper installation and maintenance procedures, and optimizing upgrades, hefty machinery owners can increase their devices's performance and durability. Investing in aftermarket components can eventually result in enhanced productivity and decreased downtime, making it a worthwhile consideration for proprietors aiming to maximize their equipment procedures.

Owners of heavy equipment can appreciate many advantages by choosing for aftermarket parts over initial tools maker (OEM) parts. Aftermarket parts are typically extra inexpensive than OEM parts, permitting machinery owners to lower upkeep and repair service costs without compromising on top quality. By meticulously examining the high quality and compatibility of aftermarket parts with their equipment, owners can strike a balance in between cost-effectiveness and performance, ultimately making best use of the performance and durability of their heavy tools.

In verdict, aftermarket parts offer countless advantages for heavy equipment owners, including cost-effectiveness, raised effectiveness, and customization alternatives. By picking the best aftermarket components, complying with proper installment and maintenance procedures, and optimizing upgrades, heavy equipment owners can improve their tools's efficiency and longevity.

Comments on “Gain a Competitive Edge: Why Aftermarket Construction Parts Are Essential for Success”